Animal Ear Tag Manufacturing Process

1. Design and Planning

RFID animal ear tags are based on the requirements of the clients and the specifics of animal identification, the size, shape, and functionality of the tag are determined.

2. Procuring Materials

We use high-quality durable plastics or silicone material. These materials provide the tag with durability and adaptability to withstand environmental conditions.

3. RFID Chip Integration

This chip is integrated into the tags, with the type of chip – low frequency (LF), high frequency (HF), or ultra-high frequency (UHF) – selected based on application requirements.

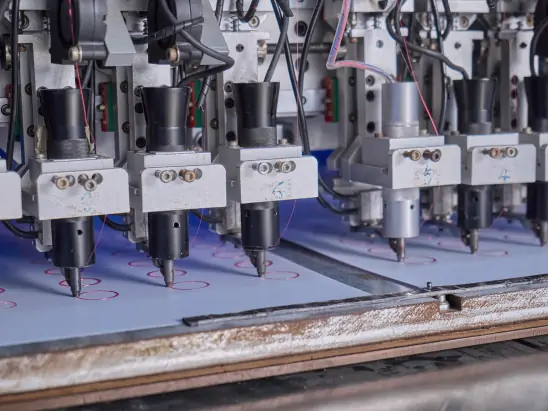

4. Manufacturing and Printing

The casing for the tag is assembled, and the RFID chip is placed using precision equipment. Information like text, logo, and personalized details are imprinted using advanced printing methods.

5. Encoding and Customization

The tag is then encoded, storing unique data such as identification numbers, owner details, or health records. The tags are further customized with brand logos or designs as per customer requirements.

6. Quality Assurance

Quality control steps are undertaken to confirm that the RFID animal ear tags meet quality standards. Tests for read range, durability, and waterproof performance are conducted.

7. Packaging for Protection

The RFID animal ear tags are encapsulated and packed to protect the RFID chips and the printed information. Appropriate packaging methods ensure the tags arrive safely during transportation.

8. Delivery and Post-sales Support

Finally, the completed RFID animal ear tags are delivered, and after-sales service is provided to address customer inquiries and offer technical support.